How to Adjust Flappers

How to fix jams with flappers, or cards going to the wrong bin (mechanical error).

Flappers are what we call the arms that move up and down, directing cards to fall into the correct bins. Being a mechanical component, they can become stuck. This can cause cards to jam, or to be sorted into incorrect bins, even when the software allocates a card correctly.

If cards are catching on the flapper and not falling into the bay, this may also be a problem with the rubber rings on the conveyor. Make sure they're lined up on top of each other to ensure cards are moving through the conveyor at the proper speed. See the following article.

To troubleshoot flapper problems, follow these steps:

Remove the Conveyor Cover by removing the cover's thumbscrew and sliding the cover off the machine, away from the scanner. Your flappers will be one of the following types. Click on your flapper type to go to the correct section:

Your flappers will be one of the following types. Click on your flapper type to go to the correct section:

3D-Printed Flappers

Check each flapper is at the same height when at rest. They should all be identical. Most importantly, they should be below the height of a card going through the conveyor, and when fully extended, should be above the leading edge of a card passing through.

- if a flapper is too low or too high, loosen the following two screws.

- use the screw on the bottom to adjust the height of the solenoid. Clockwise (if facing the screw from below) to move the solenoid up, counterclockwise for down.

- when satisfied with the height of the solenoid, retighten the two side screws

If a flapper is not moving up or down when it should, there are 2 likely possibilities as to the cause:

The Flapper is Stuck

- Make sure the flapper is not touching the rubber rings on the conveyor shafts when fully extended. If it does, slide the rings over (either to the side or the middle, depending on the ring) until they no longer make contact.

- the rings on each shaft (above and below) should be lined up

- Move the flapper up and down by hand to check if it's getting stuck. This can happen if the 3D-printed parts of the flapper assembly are touching both sides of the conveyor.

- If the flapper is catching or too tight, loosen the bolt holding the flapper, roughly 1/8th of a turn, and recheck its movement.

- Test by running ~200 low-value cards through the machine. It's important to pay attention to the cards as they reach the adjusted flapper to see if the issue (if it remains) is due to the cards not reaching the bin in time (usually a conveyor ring issue) or if the flapper is moving slowly, getting stuck, or not moving at all.

The Solenoid or Solenoid Control Board has Failed

Solenoids are the small pistons that move the flapper up and down.

With the machine processing cards and the cover removed, observe the solenoid to ensure that it is firing properly. If it does not, then the solenoid can be replaced. Solenoids are not part of the standard repair kit, contact Support if replacements are required.

With the machine processing cards and the cover removed, observe the solenoid to ensure that it is firing properly. If it does not, then the solenoid can be replaced. Solenoids are not part of the standard repair kit, contact Support if replacements are required.

- to remove a solenoid, remove the three screws pictured below, along with the grey cable (and additional cables clipped below), and pull the entire 3-solenoid assembly out, away from the conveyor

To test solenoids, swap 2 different 3-solenoid assemblies. If the issue remains in the same position, the flapper is the issue. If the problem moves, swap the solenoid on the problematic bin with another in the same assembly. If the problem moves, the solenoid is faulty, if it does not, the control board is faulty. Contact Support for replacements.

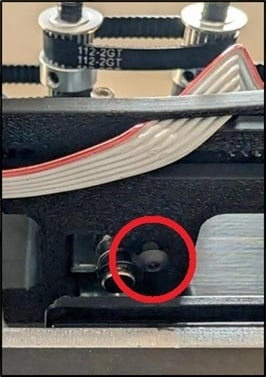

- take the solenoid out of the housing by removing the following two screws

- reinstall the new solenoid in the reverse manner to the above

- note that the metal bar coming from the flapper must be fitted back through the plastic caps on the top of the solenoid. If the cap comes off, it may be pressed back on. Using a blunt-tip screwdriver or Allen key can make this process easier.

Wire Flappers

Check each flapper is at the same height when at rest. They should all be identical. Most importantly, they should be below the height of a card going through the conveyor.

-

- If a flapper is raised higher than the others it can be bent downwards slightly by pressing on the U-bar firmly from above.

If a flapper is not moving up or down there are 3 likely possibilities as to the cause:

The solenoid control board has failed

The Flapper is Stuck

- Ensure the flapper is not touching both sides of the conveyor wall. There should be enough space that it can rest without touching either, but both is too wide.

- Empty the card bay below the flapper in question.

- Unscrew the solenoid from the conveyor, adjacent to the flapper. Let it hang loose.

- Unscrew the black bolt holding the flapper in place.

- Press down firmly on the shaft the flapper rotates on, it should drop down into the card bay.

- Check that there are no burrs on the side of the conveyor wall with your hand (something the flapper could be catching on).

- If there are any, they can be sanded off with 1000-grit sandpaper.

- If the flapper was too wide, pinch the ends of the U-bar and narrow the flapper slightly. After this, make sure the flapper can still spin freely on its shaft.

- Reinstall the flapper and solenoid in reverse order of the above. The black bolt should be snug, but not tightened to the limit. Make sure the long arm of the flapper fits into the black plastic ring on the solenoid, if that is present.

- Check the flapper for full range of motion again after reinstallation. If necessary, loosen the black bolt slightly.

- Run ~200 low-value cards through to test the machine.

The Solenoid has Failed

The solenoid is the piston that moves the flapper up. Gravity moves it down. The best way to check the solenoid is to watch it during operation to see if it is firing (moving up). For ease of testing, create a custom sort directing all cards to that particular bin (ex. Value >= 0.01). You can also move the piston with your hand to see if there's any resistance.

If you think the solenoid may be the problem but are unsure, the next step is to swap two solenoids and see if the problem moves with the solenoid in question.

- Unscrew the solenoid from the conveyor, adjacent to the flapper. Let it hang loose.

- Unscrew the black bolt holding the flapper in place.

- Press down firmly on the shaft the flapper rotates on, it should drop down into the card bay.

- Unplug the solenoid from the control board.

- Note: Do not pull from the cables, the wires going into the connector may pull out (they can be reinstalled, but it's a pain). Pull the white connector out from the socket instead.

- Note: Do not pull from the cables, the wires going into the connector may pull out (they can be reinstalled, but it's a pain). Pull the white connector out from the socket instead.

- The solenoid should now be free and can be replaced or moved.

- Reverse the process to reinstall the solenoid and flapper.

If you require a replacement solenoid, contact support.

The Solenoid Control Board has Failed

The control board handles the current going to each solenoid. The chances of this board failing are very low. If the board has failed, the most likely symptom is that all 3 solenoids attached to that board are inoperable or stuck open at all times. As with above, the easiest method to test is to swap solenoids around and see if they work on a different board, as shown above.

If you require a replacement solenoid board, contact support.